What Is a Chute?

What Is a Chute: It's History and the Mystifying Household Chute Innovation - Laundry Jet

Ever marveled at the convenience of a laundry chute, effortlessly transporting dirty clothes from upper floors to the laundry room? This ingenious invention finds its roots in the ancient concept of chute gravity, which have been used for centuries in agriculture and construction. Today, we even have modern innovations, like the Laundry Jet system, that challenge the traditional design by using powerful suction instead of chute gravity to transport laundry.

Key Takeaways

- Gravity chutes are an efficient and sustainable solution for material transportation, with modern innovations such as the Laundry JET system providing a more energy-efficient alternative.

- Design considerations should take into account factors such as incline and slope, material flow and velocity, safety and maintenance in order to ensure effective operation.

- Gravity chutes promote eco-friendly practices by reducing operational costs while minimizing manual handling of materials.

The Fundamentals of Gravity Chutes

The concept of chutes has been around since the very beginning of human civilization, with gravity chutes first appearing in ancient agriculture and construction to move goods and materials downwards. Over time, the Industrial Revolution revolutionized chute technology, replacing traditional materials like wood and stone with metal and plastic.

Defining a chute as a sloping channel or passage for conveying materials, these devices have a wide range of applications in various industries. The term “chute noun” refers to the word chute used in this context.

How Gravity Chutes Work

Gravity chutes function based on a simple principle: items on the chute’s incline are pulled downwards by the force of gravity. The speed and flow of materials are determined by the chute’s incline and slope. Steeper chutes facilitate faster movement. Items sliding down the incline are accelerated by the force of gravity, which controls their descent and guarantees a continuous flow.

In skydiving, the main parachute serves as a type of chute that slows down the descent of a person or object, using air resistance to counteract the force of gravity. Similarly, in a gravity chute, the angle of the slope influences the capacity and efficiency of the chute, ensuring that materials move smoothly and at an appropriate speed.

Materials and Construction

Chutes can be constructed from a variety of materials, depending on their application and requirements. Traditional chutes were made from wood and stone, while modern chutes are often built using metal or plastic materials. Aluminum, iron, steel, and resilient plastics are commonly used in gravity chute construction due to their durability and ability to provide a smooth surface for material flow.

Each material used in chute construction has its advantages and drawbacks. Metal chutes, for example, are durable but can be more costly and generate more noise compared to plastic or rubber alternatives. Plastic chutes, on the other hand, are lightweight, corrosion-resistant, and easy to install, making them a practical choice for many applications.

Selecting materials for gravity chutes requires a consideration of their durability, resistance to chemicals or moisture, and the flowability characteristics expected of the materials they will handle.

Exploring the Role of Gravity Chutes in the Context of Laundry Chutes

Gravity chutes are versatile and find applications in various industries, from industrial manufacturing and building construction to waste management.

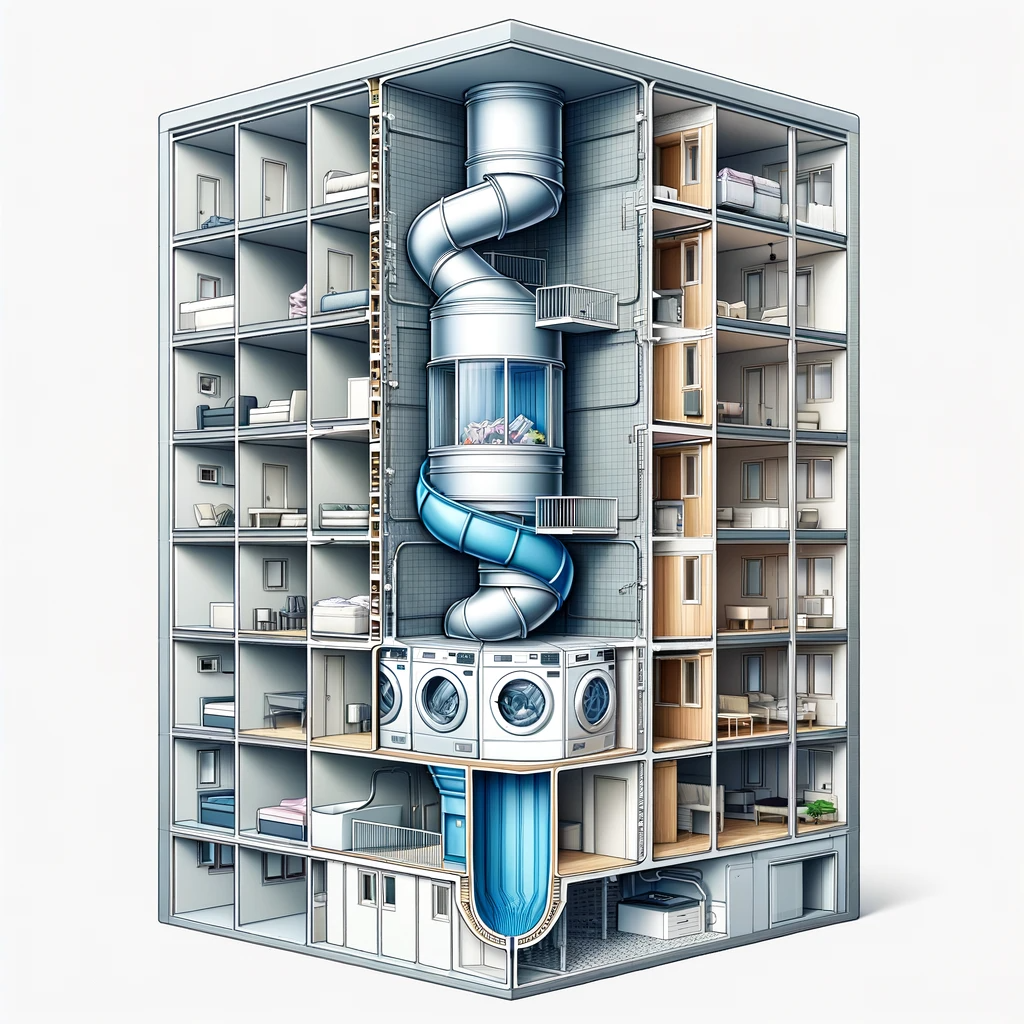

Laundry chutes, also known as laundry chute systems, serve as a convenient and secure method for transporting dirty laundry from upper floors to lower floors, such as a centralized location like a laundry room or basement.

Industrial and Manufacturing

In industrial settings, gravity chutes play a vital role in the transportation of materials and goods. They are often used in conveyor systems to ensure consistent and efficient movement of materials, reducing the risk of damage or breakage while also decreasing the need for manual handling. The use of gravity by these chutes enhances industrial process efficiency, leading to productivity increment and cost reduction.

Gravity chutes can handle a wide variety of materials, including:

- Powders

- Grains

- Mineral ore

- Coal

Correct design, regular inspections, and maintenance are necessary for the safe operation of chutes in industrial environments. Implementing safety features and devices, providing training to employees, and following proper manual handling techniques can help minimize the risk of accidents and injuries in the workplace.

Building and Construction

Gravity chutes are fundamental in the building and construction industry as they provide a safe and convenient method to transport waste materials like wood, metal, and construction debris from higher to lower levels. By reducing the need for manual labor and minimizing the risk of accidents, these chutes improve efficiency and safety on construction sites.

Besides waste management, gravity chutes also have the following benefits:

- Transport construction materials to workers on higher floors

- Eliminate manual handling and increase safety

- Improve overall productivity and efficiency on construction sites.

Waste Management

Gravity chutes play a critical role in waste management systems, allowing for efficient collection and transportation of waste materials. By utilizing the force of gravity, these chutes can transport waste from higher levels to lower levels, where it can be collected, sorted, and disposed of.

In addition to their use in waste collection, gravity chutes can also be integrated with pneumatic chutes for more advanced waste management solutions. This combination allows for the efficient transportation and disposal of waste materials, contributing to a cleaner and more sustainable environment.

Design Aspects to Consider for Gravity Chutes, Especially in Relation to Laundry Chutes

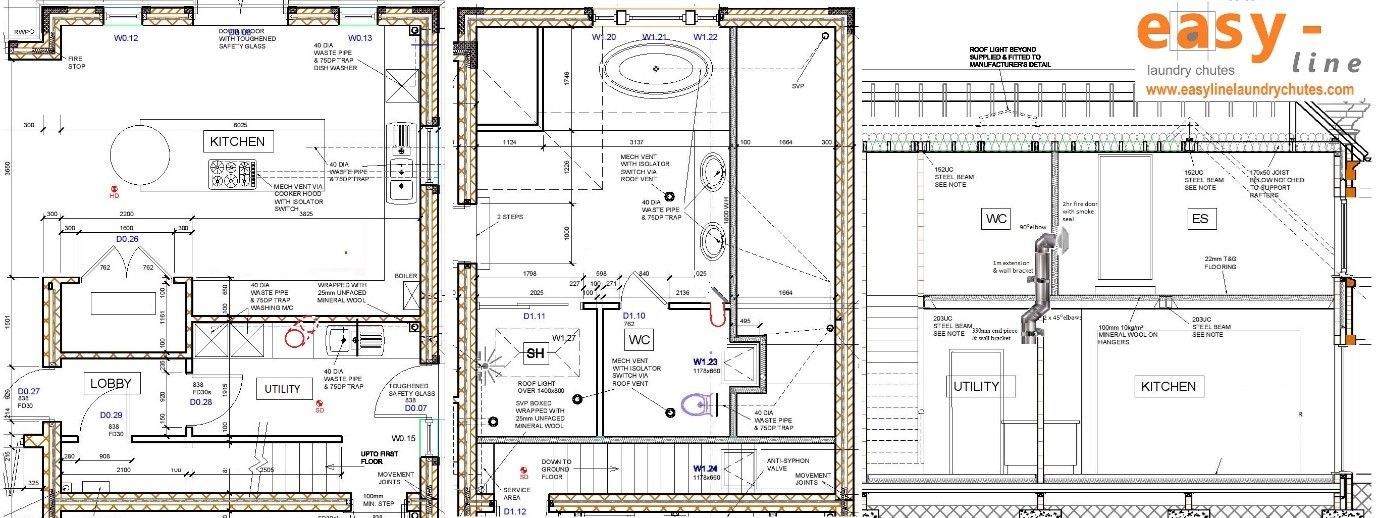

Designing gravity chutes, particularly for laundry chutes, necessitates the careful consideration of factors like incline and slope, material flow and velocity, along with safety and maintenance. These factors ensure efficient and safe transportation of materials, whether in an industrial setting or within a residential building.

Incline and Slope

The incline and slope of a chute play a significant role in determining the speed and flow of materials. Here are some key points to consider:

- A steeper chute results in a faster rate of movement.

- A more gradual slope can lead to slower, more controlled movement.

- The angle of the slope influences the capacity and efficiency of the chute.

- It ensures that materials move smoothly and at the appropriate speed.

When designing a gravity chute, it’s important to consider the following:

- The properties of the materials being transported

- Any routing restrictions or containment requirements

- The suitability of the incline for the weight and fragility of the items being transported

A steeper incline may not be suitable for heavy duty, heavier or more delicate items, as they could become damaged or obstruct the chute if they do not slide smoothly.

Material Flow and Velocity

Material flow and velocity are important factors in chute design, ensuring the efficient and safe transportation of items. The velocity of flow down the inclined surface and the rate of erosion of the chute surface are essential considerations when designing a gravity chute. Proper chute design can help prevent blockages, reduce wear and tear on equipment, and maintain a consistent flow of materials.

The flow and velocity of materials in a smooth chute can be influenced by factors such as the material’s properties, the angle of discharge chute, the slope, and the chute’s design. By taking these factors into account, designers can create a chute that provides efficient, smooth, and safe transportation of materials.

Safety and Maintenance

Ensuring the safety and proper maintenance of gravity chutes is essential for their continued efficiency and longevity. Regular inspections, proper installation, and addressing potential hazards are all crucial aspects of maintaining a safe and functional chute system. Gravity chutes should be inspected for maintenance requirements at least annually to prevent any issues from arising.

Some potential hazards associated with gravity chutes include:

- Falling objects

- Pinch points

- Slips and falls

- Equipment malfunction

- Electrical hazards

By addressing these hazards and taking the necessary precautions, users can ensure the safe and efficient operation of their chute system.

Modern Innovations in Chute Technology

Modern chute technology innovations like the Laundry Jet system challenge the traditional design of gravity chutes by employing powerful suction for transportation instead of gravity. This innovative approach can be compared to the elegance and efficiency of French engineering, much like the smooth flow of a river or the thrill of riding a water chute.

This modern approach to laundry chutes provides users with a more convenient and efficient method for managing their household laundry tasks.

The Laundry Jet System

The Laundry Jet system is designed with simplicity and convenience in mind, allowing users to insert their dirty laundry into a port for efficient transport to the laundry room. Unlike traditional gravity chutes, the Laundry Jet system uses a vacuum-powered mechanism to generate a suction that draws the laundry through the chute, transporting it in a matter of seconds.

Constructed using a system of tubes and wall-installed ports, the Laundry Jet system relies on air power to transport laundry from any room with ports installed to the laundry room. This innovative technology offers users a more efficient and environmentally friendly alternative to traditional gravity chutes.

Cost and Installation

Depending on the size, number of ports, and complexity of the system, a Laundry Jet system might cost anywhere between $2,400 and $15,000. Factors that influence the cost of a Laundry Jet system include the type and model chosen, the size and complexity of the installation, and the cost of piping and other necessary components.

While the installation of a Laundry Jet system can be a DIY project for those with experience, it is advisable to seek professional assistance if you are unfamiliar with similar installations. Proper installation is crucial for the system to function efficiently and safely, ensuring that your investment in this innovative technology is worthwhile and long-lasting.

Optional Return System

The Laundry Jet system offers an optional return system for clean laundry, adding another layer of convenience for users. This return system operates by drawing the clean laundry up to a predetermined location inside the residence, making it easy to retrieve and put away after washing and drying.

The additional cost of the optional return system for the Laundry Jet system depends on the size and number of ports and can range from $2,400 to $15,000, to be added to the overall cost. This convenient feature further enhances the efficiency and user-friendliness of the Laundry Jet system, making it a worthwhile investment for busy households.

Gravity Chutes in Everyday Life

Gravity chutes can be found in everyday life, from mail chutes in multi-story buildings to laundry chutes in residential homes. These simple yet ingenious devices offer a convenient and efficient method for transporting items within a building, relying on the natural force of gravity to do the work.

Mail Chutes

Mail chutes provide an efficient method for delivering mail within multi-story buildings, using gravity to transport letters and packages from upper floors to a central collection area on the ground level. These chutes and doors are typically constructed of glass and run the length of the building, with a mailing slot on each floor for easy mail insertion.

Invented by James Goold Cutler in the fall of 1883, mail chutes revolutionized mail delivery within large buildings, offering a convenient and efficient method for residents and workers to send and receive mail. Today, mail chutes continue to play an important role in mail delivery, especially in older buildings where they are still in use.

Laundry Chutes

Laundry chutes provide a convenient method for transporting dirty laundry from upper floors to a central laundry room in residential settings. These chutes eliminate the need for carrying heavy laundry baskets up and down stairs, making laundry day a more efficient and enjoyable task.

The history of laundry chutes dates back to the 1800s when they were first introduced in Victorian homes as a symbol of wealth and good health. Today, laundry chutes are a common feature in many residential buildings, providing a practical solution for managing household laundry tasks.

Environmental Impact and Sustainability

The environmental impact and sustainability of gravity chutes are important considerations in today’s eco-conscious world. As energy-efficient devices that rely on the natural force of gravity for transportation, gravity chutes offer an environmentally friendly alternative to more energy-intensive methods of material transport.

Energy Efficiency

Gravity chutes are naturally energy-efficient because they rely on the natural force of gravity for transportation, which reduces the need for extra power sources. This makes them a more eco-friendly option compared to other material transportation methods, such as conveyor belts or elevators, which require electricity to operate.

The energy efficiency of gravity chutes can have a significant impact on operational costs, as they:

- Require fewer moving parts

- Require less maintenance

- Reduce energy consumption

- Promote environmentally friendly practices

By implementing gravity chutes, businesses can contribute to a more sustainable future.

Sustainable Alternatives

The Laundry Jet system is an example of a sustainable alternative to traditional gravity chutes, as it uses powerful suction to transport laundry rather than relying on gravity. This innovative technology offers a more energy-efficient and environmentally friendly option for managing household laundry tasks.

In addition to the Laundry Jet system, other sustainable alternatives to gravity chutes include automated variable flow control systems, recycling chutes, and conveyor systems. These alternatives offer more environmentally friendly options for material transportation, helping to reduce the carbon footprint and promote eco-friendly practices in various industries.

Summary

In conclusion, gravity chutes play a vital role in various industries and everyday life, offering a convenient and efficient method for transporting materials and items. From their historical origins in ancient agriculture and construction to modern innovations like the Laundry Jet system, chutes continue to evolve and adapt to meet the needs of our ever-changing world. By considering factors such as energy efficiency, sustainability, and safety, we can continue to harness the power of gravity to improve our lives and protect our planet for future generations.

Frequently Asked Questions

What are the three types of chutes?

The three types of chutes are gravity chutes, belt chutes and slide chutes. Gravity chutes rely on the force of gravity to move objects down a steep slope, while belt chutes utilize a conveyor belt system to transport items. Slide chutes, on the other hand, use an inclined plane with a low coefficient of friction to achieve controlled descent.

What is the purpose of a chute?

Chutes are used in industry to transport material between processes, as well as in tall buildings to quickly move items from higher floors to lower levels. Chutes may come in the form of a variety of shapes, such as round, square or rectangular at the top and bottom.

What does chute mean UK?

Chute in the UK is typically used to describe an inclined channel or trough on a steep slope, allowing for things like water, parcels, and coal to be dropped down, or as a slide for toboggans.

How does a gravity chute work?

A gravity chute device uses the force of gravity to move items down an inclined slope, controlling the speed and flow of the materials.

What are the typical applications of gravity chutes in industries?

Gravity chutes are frequently employed in industries such as industrial manufacturing, building and construction, and waste management to facilitate the transportation of materials and goods.

Need more help with the Laundry Jet or any chute requirement needs, contact us today!