Laundry Chutes: Engineering a Chute

Introduction

Laundry chutes, those unassuming conduits discreetly embedded in homes and buildings, serve a much more significant role than one might initially perceive. This architectural feature, often hidden behind a small door or seamlessly integrated into the building's design, embodies a unique blend of practicality and engineering ingenuity. In this comprehensive exploration, we'll delve into the multifaceted world of laundry chutes, uncovering the sophisticated engineering principles that underpin their design and functionality.

At their core, laundry chutes are about enhancing efficiency and convenience in both residential and commercial buildings. They offer a simple yet effective solution for transporting laundry from upper floors directly to a designated laundry room or collection area. However, the straightforwardness of their purpose belies the complexity and thoughtfulness of their design. From structural considerations and material selection to specialized implementations in diverse settings like healthcare facilities, the engineering of laundry chutes encompasses a broad spectrum of disciplines and considerations.

In the following sections, we'll journey through the historical evolution of laundry chutes, their basic engineering principles, and the myriad safety considerations integral to their design. Special attention will be given to their role in healthcare settings, where they take on additional significance in infection control and operational efficiency. Whether in a cozy family home or a bustling hospital, laundry chutes represent a fascinating intersection of everyday convenience and sophisticated engineering, demonstrating how even the most mundane aspects of our built environment can be transformed through thoughtful design.

Historical Evolution of Laundry Chutes

The story of laundry chutes begins in the late 19th and early 20th centuries, a period marked by rapid urbanization and the development of multi-story buildings. Initially, these chutes were a luxury feature in hotels and affluent homes, designed to add convenience by easily transporting laundry to a central collection point, usually in the basement.

Early Designs and Popularity

Early laundry chute designs were relatively rudimentary, often little more than simple vertical shafts built into the walls. However, they quickly gained popularity, becoming a coveted feature in new constructions. Their appeal lay not only in their practicality but also in the way they reflected the era's fascination with novel conveniences and domestic efficiency.

The Role of Laundry Chutes in the Progressive Era

During the Progressive Era in the United States, there was a strong focus on improving living conditions and household efficiency. Laundry chutes were seen as a means to streamline domestic chores, a sentiment echoed in the writings of home economists and domestic advice literature of the time. They were no longer just a convenience but a tool for improving domestic management.

Mid-20th Century Innovations

As architectural styles and building technologies evolved through the 20th century, so did the design of laundry chutes. They began to feature more sophisticated materials, such as stainless steel, and incorporated safety and convenience features like fire-resistant doors and easy-access hatches. This period also saw the integration of laundry chutes into a wider range of buildings, including modest family homes and commercial establishments.

Decline and Resurgence

In the latter half of the 20th century, the popularity of laundry chutes waned somewhat, possibly due to changing architectural trends and the advent of lightweight, portable laundry baskets. However, they saw a resurgence in popularity towards the end of the century and into the 21st century, particularly in custom home designs and renovations where convenience and vintage charm are valued.

Conclusion

The history of laundry chutes reflects broader trends in architecture, domestic technology, and societal attitudes towards household management. From a symbol of luxury and modernity to a practical tool for efficiency, laundry chutes have adapted to the changing times while maintaining their core purpose – to make life a little easier, one floor at a time.

Basic Engineering Principles of Laundry Chutes

The engineering of laundry chutes involves a harmonious blend of structural design, material science, and user-centric considerations. This section delves into these fundamental principles, highlighting the technical sophistication behind these seemingly simple systems.

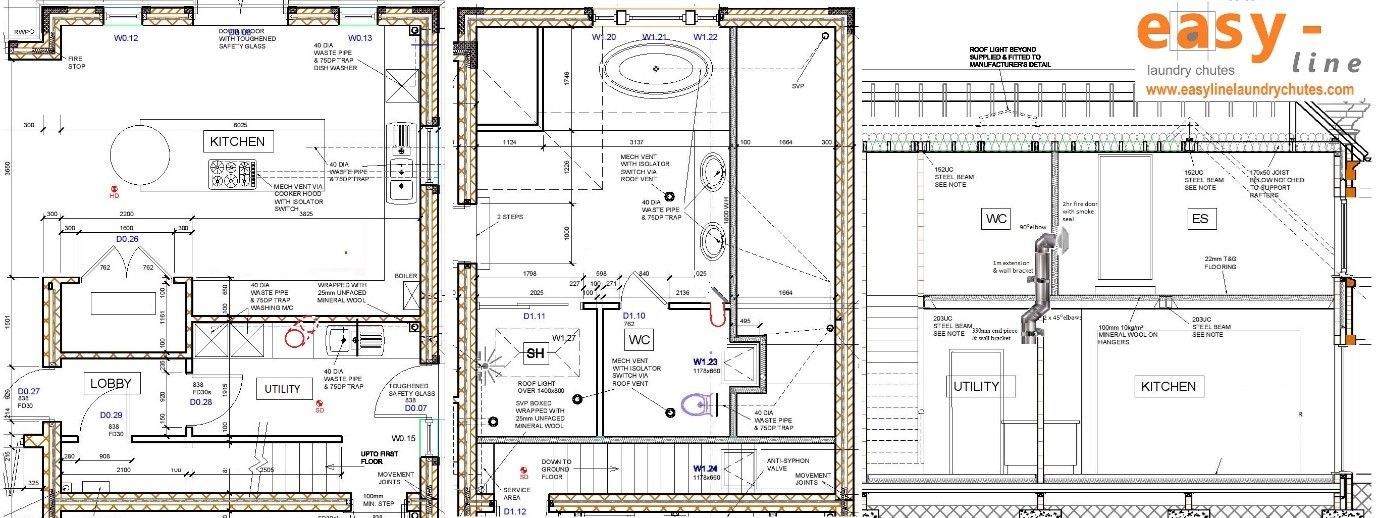

Structural Integration

Integrating a laundry chute into a building requires meticulous structural planning. Engineers must ensure that the chute's placement does not compromise the building's structural integrity. This involves calculating the load-bearing capacity of the walls or floors where the chute will be installed. The chute must be designed to fit seamlessly into the existing structure, often requiring custom solutions for different buildings.

Material Selection

Choosing the right materials for a laundry chute is crucial for its durability, functionality, and safety. Materials must be robust enough to withstand constant friction and the weight of laundry. Stainless steel is often preferred for its strength, durability, and fire resistance. The choice of material also considers aspects like noise reduction, maintenance ease, and aesthetic compatibility with the building's interior design.

Aerodynamics and Fluid Dynamics

The principles of aerodynamics and fluid dynamics play a vital role in the efficient functioning of laundry chutes. Engineers must consider how laundry descends through the chute, ensuring a smooth, unobstructed flow. This involves designing the chute's size and shape to accommodate various types of laundry while preventing clogs. The placement and design of vents are also critical to manage air pressure and prevent backdrafts, ensuring safety and efficiency.

Noise Reduction Techniques

In residential settings, particularly, reducing the noise created by items descending the chute is a significant concern. Engineers employ various noise-dampening techniques, including using materials that absorb sound and designing the chute's path to minimize the impact of falling objects.

User Accessibility and Ergonomics

Laundry chutes must be designed with the end-user in mind. This includes considering the height and placement of the chute's entrance, ensuring it is accessible for all users, including children and people with disabilities. The design should also prioritize ease of use, with user-friendly mechanisms for opening and closing the chute.

Compliance with Building Codes and Safety Regulations

Laundry chutes must comply with local building codes and safety regulations. This includes ensuring they meet specified dimensions, adhere to fire safety standards, and incorporate necessary ventilation systems. Compliance not only guarantees the chute's safety but also its longevity and efficiency.

Through these engineering principles, laundry chutes are transformed from a simple concept to a sophisticated and integral part of modern building design, enhancing convenience and functionality in both residential and commercial settings.

Safety Considerations in Laundry Chute Design

Safety is a paramount concern in the design and implementation of laundry chutes. These considerations are not just about adhering to regulations; they are integral to ensuring that the chute functions effectively and safely for all users.

Fire Safety and Prevention

One of the most critical safety aspects of laundry chute design is fire prevention. Engineers must incorporate materials that are fire-resistant and design the chute to prevent the spread of flames in case of a fire. This might include installing fire-rated doors at each entry point and ensuring that the chute itself does not act as a conduit for fire to travel between floors.

Child and Pet Safety

In residential settings, the safety of children and pets is a significant consideration. Laundry chutes must be designed to prevent accidental falls or injury. This could involve safety locks, doors that are difficult for children and pets to open, or designing the chute's entrance in a way that is not easily accessible to them.

Compliance with Building Codes

Adhering to local building codes and safety regulations is essential. These codes often dictate the minimum and maximum dimensions of the chute, fire safety requirements, and necessary ventilation. Compliance ensures that the chute meets safety standards set by authorities and reduces the risk of accidents.

Ventilation and Air Quality

Proper ventilation is crucial in laundry chute design. Adequate air flow prevents the buildup of lint and other debris, which could pose a fire hazard. It also ensures that any potentially harmful fumes or odors are adequately vented out of the building.

Emergency Access and Maintenance

Designing for easy access in case of emergencies is another safety aspect. This includes features like access panels or doors that allow for quick maintenance or emergency interventions. Regular maintenance access is also important to ensure the chute remains clean and free of obstructions, further reducing safety risks.

In conclusion, safety considerations in laundry chute design encompass a broad range of aspects, from fire prevention and child safety to compliance with regulations and emergency preparedness. These elements are crucial to ensure that the convenience of laundry chutes does not come at the expense of the safety of the building's occupants.

Specialised Design for Healthcare Facilities

In healthcare settings, the design and engineering of laundry chutes demand additional, specialized considerations, primarily due to the unique challenges and requirements of these environments.

Enhanced Infection Control

Infection control is a primary concern in hospitals and healthcare facilities. Laundry chutes in these settings are designed to minimize the risk of cross-contamination between different areas of the facility. Materials used for the chute might have antimicrobial properties, and the design ensures that laundry is handled in a way that reduces the possibility of spreading infectious agents.

Compliance with Health Standards

Laundry chutes in healthcare facilities must comply with stringent health and safety standards. This includes using non-porous, easy-to-clean materials that can withstand frequent sanitization. The design also ensures minimal human contact with the laundry, reducing the risk of contamination.

Efficient Workflow Design

Efficiency is critical in healthcare settings. Laundry chutes are strategically placed to reduce the time and effort required by staff to handle soiled linens, thereby improving overall workflow. This placement also considers the best routes for transporting laundry while avoiding areas with high patient traffic or sensitive equipment.

Special Safety Features

Given the diverse range of users in a hospital, including staff, patients, and visitors, safety features in laundry chutes are essential. This includes lockable access to prevent misuse, design elements that prevent accidental falls, and mechanisms that are easy to use even by those with limited mobility.

Conclusion

In the context of healthcare facilities, laundry chutes are not just a convenience but a critical component of the facility's operational efficiency and infection control strategy. Their design reflects the unique challenges of these environments, balancing efficiency, safety, and compliance with health standards to support the critical work of healthcare professionals.

Laundry Chutes in Residential and Commercial Buildings

Residential Applications

In residential settings, laundry chutes are designed with a focus on convenience and space-saving. They often feature simpler designs, tailored to blend with the home's aesthetics. Safety, especially in homes with children, is a key consideration, leading to features like child-proof locks.

Commercial Implementations

In commercial buildings, such as hotels or large office complexes, laundry chutes are larger and more robust. They are designed for high-volume usage, often incorporating advanced safety features and fire-resistant materials. Their placement is strategic, aimed at maximizing efficiency in laundry handling.

Environmental and Sustainability Considerations

Eco-friendly Materials

Modern laundry chute designs increasingly incorporate sustainable materials that reduce environmental impact. Recycled metals or sustainable composites are options that align with green building practices.

Energy Efficiency

Design considerations also include energy efficiency, such as minimizing the chute's impact on a building's heating and cooling systems. This can be achieved through insulation and strategic placement.

Future Trends and Innovations

Technological Integration

Future laundry chutes might incorporate smart technology for enhanced functionality, like sensors to monitor usage or blockages, and automated doors for improved efficiency and safety.

Design Innovations

Emerging designs could include modular and adaptable systems that can be easily installed in existing structures, and aesthetically pleasing options that complement modern interior designs.

These points illustrate the diverse applications and future potential of laundry chutes, reflecting their evolution from simple utility fixtures to sophisticated components of modern architecture.

Conclusion

In conclusion, the engineering of laundry chutes epitomises how a blend of design, functionality, and safety can enhance our daily lives. From their historical origins to modern applications in various settings, including the critical environments of healthcare facilities, laundry chutes illustrate the importance of thoughtful engineering. They represent a unique intersection of practicality and innovation, constantly evolving with emerging technologies and sustainability considerations. As we move forward, laundry chutes will undoubtedly continue to reflect the changing dynamics of architecture and design, remaining a subtle yet integral part of our built environment.